low voltage construction overhead concentric cable in power cables

| Port: | any port in China |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram |

| Supply Ability: | 50000 Meter/Meters per Week |

| Place of Origin: | Henan China |

| Brand Name: | Sitong |

| Model Number: | concentric cable |

| Insulation Material: | PVC/PE/XLPE |

| Type: | aluminum/copper |

| Application: | power transmitter |

| Conductor Material: | aluminum or copper |

| Jacket: | PVC/PE/XLPE |

| Product name: | low voltage construction overhead concentric cable in power cables |

| keywords: | power cable for construction |

| oem: | avilable |

| Certificate: | iso/ccc |

| application: | power transmission |

| Voltage: | 0.6/1KV AC 1.8KV DC |

| Conductor type: | overhead |

| Core: | Copper or alunium Core |

| keywords 2: | submarine power cable |

| keywords 3: | concentric cable |

| Packaging Detail: | standard packing as customized and China standard. usually use wooden drum. |

8AWG/6AWG/4AWG copper or aluminum concentric electrical cable

Range:

|

CODES |

DESCRIPTION |

|

1006191 |

copper concentric conductor 2X # 10 AWG |

|

1006017 |

copper concentric conductor 2X # 8 AWG |

|

1006202 |

copper concentric conductor 3X # 8 AWG |

|

1006015 |

copper concentric conductor 3X # 6 AWG |

|

1006014 |

copper concentric conductor 3X # 4 AWG |

|

1009444 |

aluminum concentric conductor 2X #8 AWG |

|

1009445 |

aluminum concentric conductor 3X # 8 AWG |

|

1009443 |

aluminum concentric conductor 3X #6 AWG |

|

|

aluminum concentric conductor 3X #4 AWG |

|

|

aluminum concentric conductor 3X #2 AWG |

NORMS

the concentric conductors of copper and aluminum, is entirely consistent with the rules ASTM D 790, D 1248, D 2655, D 2656, UL 854, UL 44, numeral NEC 310.14, and the list provided in Annex 1 to this specification.

CONSTRUCTIVE CHARACTERISTICS

Each material used in the conductor will be compatible with all other materials used in the manufacture of concentric conductor.

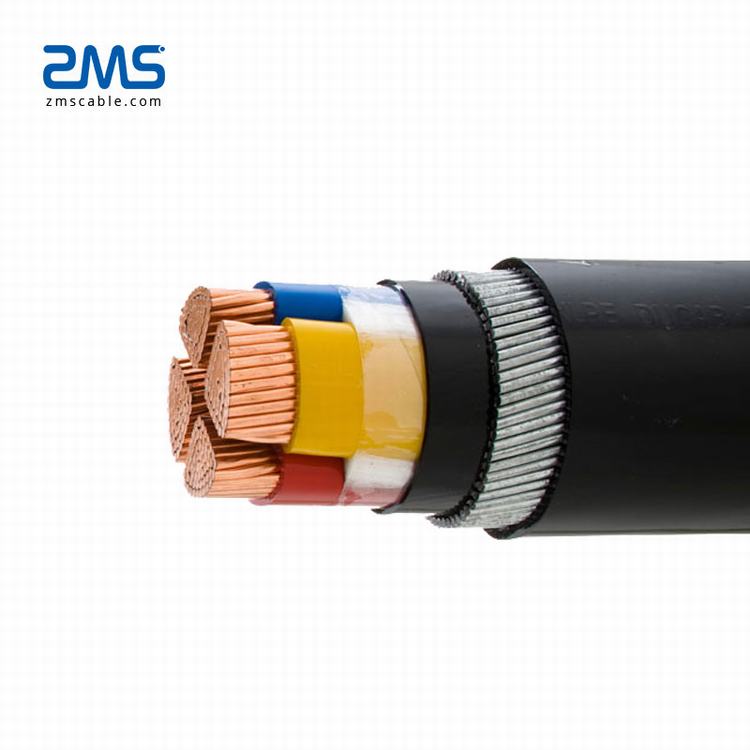

Concentric conductor consists of one or two conductors which in turn are coated with a bare conductor distributed helically around the conductors.

According to these configurations will have a phase and outer concentric neutral (bipolar), or two phases and these external neutral (tripolar)

Section of all conductors that form the concentric conductor of both phases as the concentric neutral is the same.

Conductor:

The materials used in the manufacture of concentric copper conductors shall consist of soft copper wires class B and the composition of a pure copper will never lower than 99.85 and the concentric aluminum conductors formed by wires keychain aluminum alloy 8000 series (AA-8000).

Copper wires and aluminum shall comply with the provisions of ASTM B 3 standard and UL 854.

For bipolar concentric conductor, standard sections are # 8 and 10 AWG.

For tripolar concentric conductor, standard sections are # 8, 6, 4 y 2 AWG.

In the phase conductors with 7 wires, will be able to perform welding copper wires during wiring. Once this process is completed it will not be allowed two welds closer than 15m (50ft)

According to paragraph 6 of ASTM B 8, the wiring process will be as follows:

Over the central conductor will be braided the rest of the layers. Braiding step will be at a distance to vary between 8 and 16 times the outside diameter. The lay direction of the copper wires in the outer layer will be right.

Isolation:

Each phase conductor will contain an insulating layer of XLPE for a temperature of 90 C. in the bipolar cables, over the insulating layer will be the braided neutral conductor helically with a passage between 8 and 16 times the outer diameter. In the tripolar cables over the isolation of each phase will have a PVC insulation filling in the joint of both cables and over this will be placed the neutral conductor.

Will be put over the concentric neutral conductor a tape and over this outer layer of XPLE. Must ensure the tightness of the set plus adequate resistance to ultraviolet rays (UV).

This last layer besides adding firmness should be smooth in appearance and will not be observed depressions caused by unfilled spaces beneath this layer.

Should not produce bubbles, cuts, tears or the presence of foreign materials that are detectable to the naked eye. Besides the envelope will be well centered.

The disposition of the tape around the bare conductor shall be performed as follows:

A single layer of tape with a convenient width helically applied without wrinkles or folds and with an overlap of at least 6mm. The tape will consist of nylon, with a thickness of at least 0.09mm.

Covering the entire concentric conductor will be placed a XLPE coating according the ASTM D 790, D 1248, D2655, and D2656 Standards.

The color of conductor insulation should be:

-Black: 2x #8, 2x #10

– When more than one phase will be distinguished by the black, blue and red colors.

Packaging Details : wooden drums or in coils, we have more than 20 types in total.

Port : Qingdao / shenzhen / Shanghai , any port in China.

Lead Time : according to the order 10-20 working days.

Zhengzhou Sitong Cable Co., Ltd. is a wire and cables' manufacturer, engaged in this fields more than ten years, we specialize in producing and exporting all kinds of wires and cable. we have advanced tech-staff and advanced equipment.

Our certification

Main products:

ABC cable (Duplex / Triplex / Quadruplex service drop cable)

bare conductor (AAC / AAAC / ACSR bare conductor .)

Flora Lee(Ms.)

—————————-

Zhengzhou Sanhe Cable Co.,Ltd.(Trading Company)

Zhengzhou Sitong Cable Co.,Ltd.( Production Plant )

Phone: +86 371 65341360/69176007

Fax: +86 371 69176006

Mobile:+86 15824811325

Mail:st03@)sitongcable.com

Web:http://www.sanhecable.com.cn

http://www.cnzzcable.com.cn

http://www.sitongcable.com

QQ ID: 276637971 Wechat ID:0086 15824811325

Skype ID: st03@)sitongcable

WhatsAPP ID:0086 18838288457

- Next: aluminum / copper conductor concentric cable overhead cable

- Previous: Triplex ABC … Triplex ABC Cable, Triplex Service Drop ABC Cable, Overhead Triplex ABC Cable